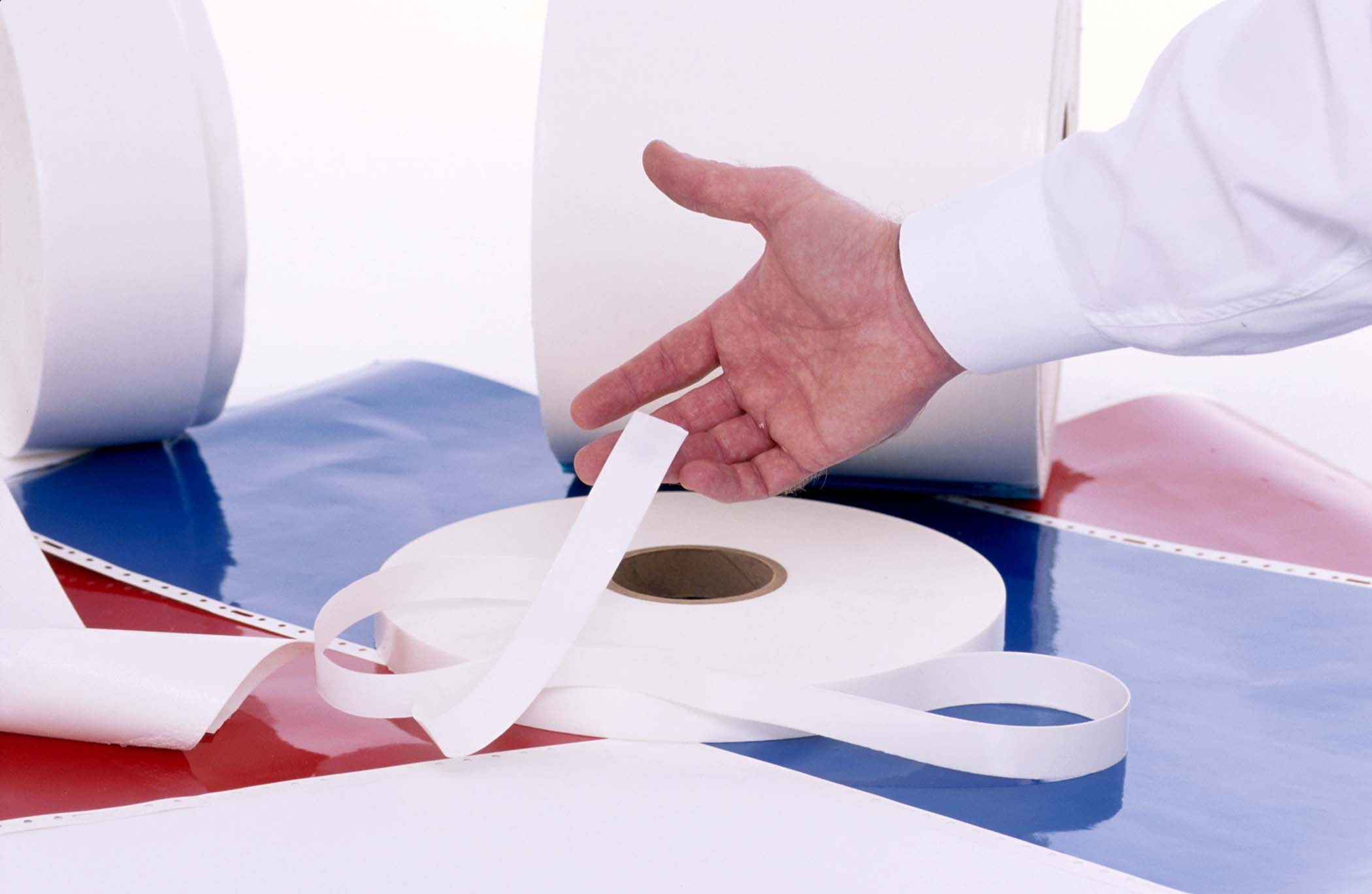

When it comes to vinyl graphics, the role of application tape is often understated, yet it’s a vital component in ensuring a flawless finish. This guide delves into the uses and benefits of this material, highlighting its significance in the vinyl graphics industry. Beyond merely being a tool for transfer, this tape plays a crucial role in preserving the integrity and design of the graphic during the application process.

Understanding the Role of Application Tape in Vinyl Graphics

Vinyl graphics are everywhere, from signage to vehicle wraps and custom t-shirts. The success of these graphics heavily depends on the precision and ease of transfer, which is where the focus material steps in. It temporarily holds the vinyl graphic in place, ensuring it adheres smoothly to a surface without wrinkles or bubbles. This transfer material is crucial for complex designs or graphics on uneven surfaces. Its use not only simplifies the process but also significantly enhances the final appearance of the graphic.

Types and Selection: Finding the Right Fit

Not all these tapes are created equal. They come in different types, such as paper or clear plastic, each with unique properties. Paper tapes are often more porous, allowing air to escape and reducing the chances of bubble formation. On the other hand, clear tapes provide the advantage of transparency, making it easier to position the graphic accurately. The choice largely depends on the project’s specific requirements and personal preference. Understanding the characteristics of each type is essential for selecting the most suitable one for your project.

Application Techniques for a Perfect Finish

Applying vinyl graphics is a skill that requires patience and precision. The technique involves removing the backing paper from the vinyl, applying the tape, and then using a squeegee to smooth out any air bubbles. The trick is to apply even pressure and work slowly to avoid tearing the graphic. It’s also important to consider the surface to which the graphic will be applied; ensuring it’s clean and smooth can make a significant difference in the result. Mastery of these techniques can greatly reduce the likelihood of errors and rework, saving both time and resources.

Troubleshooting Common Challenges

Even with the right tools and techniques, issues can arise. One common problem is the transfer material not releasing the vinyl easily. Adjusting the pressure applied during the transfer process can often address this. Another issue is the formation of bubbles or wrinkles. These can be smoothed out with a squeegee, but in some cases, it may require lifting the vinyl and reapplying it. Learning to anticipate and effectively address these challenges is key to mastering the application process.

Maintaining and Storing Your Transfer Material

Proper maintenance and storage of this material are essential for its longevity and effectiveness. It should be stored in a cool, dry place away from direct sunlight. Keeping it free from dust and debris also ensures it doesn’t transfer any unwanted particles onto the vinyl graphic. Also, proper care and handling can extend the tape’s life, making it a more cost-effective solution in the long run.

Conclusion

Application tape is an indispensable tool in the world of vinyl graphics. Its ability to facilitate accurate and smooth transfers makes it a staple in any graphic installation process. Whether you’re a professional or a DIY enthusiast, understanding and utilising this tool effectively can greatly enhance the quality of your vinyl graphic projects. Carefully selecting and applying the right transfer material is the key to a flawless finish. With the right knowledge and skills, anyone can achieve professional-level results in their vinyl graphic applications.